8HP Liquid Pump

See this product on the NEW Fluid Process Control website!

Description

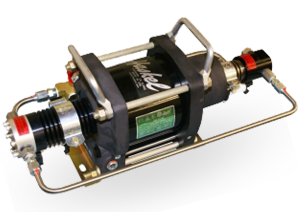

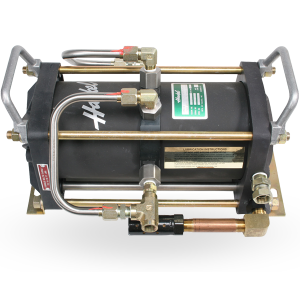

Haskel Model 8DSFD-100 8HP Air-Driven Liquid Pump

Catalog literature: Liquid Pump Catalog.pdf

With a nominal ratio of 100:1, the Haskel model 8DSFD-100 8HP air-driven liquid pump utilizes a single to boost liquid pressures to a maximum of 10,000 PSIG.

Features & Benefits:

- Safe pneumatic operation – no heat, flame or spark risk

- Infinitely variable cycling speed

- Stall at pre-determined pressure to hold that pressure without consuming power

- Problem-free stop/start applications

- Easily automated – many modification and control options

- Suitable for most liquids and liquefied gases

- Alternative gas drive options available, such as sour gas, natural gas, boil off gases, or nitrogen

- Robust, reliable, compact and easy to maintain proven design

- No need for air line lubrication – saves costs and prevents contamination

- Unbalanced cycling spool provides immediate response to pressure changes

- Can be manufactured to meet ATEX, CE and NACE requirements

Technical Data:

- Power: 8HP

- Air Head: single

- Max Air Pressure: 125 PSIG

- Max cycles: 50/min.

- Nominal ratio (“dash number”): 100:1

- Actual area ratio: 112:1

- Max outlet pressure (continuous): 10,000 PSIG

- Max outlet pressure (intermittent): 10,000 PSIG

- Displacement / cycle: 3.52 cu. in.

- Max flow: 669 cu. in./min.

Typical Performance Characteristics (@100 PSIG air supply pressure):

- 555 in3/min @ 5,000 psig

- 163 in3/min @ 10,000 psig

Materials of Construction:

- Pump section: Separation – all SS & Bronze

- Plunger: Hard chrome-plated 15-5PH SS

- Non-metallics: UHMWPE, Viton, PTFE, Ryton

Applications:

- Service Code 1: Petroleum-based oils, kerosene, ethylene glycol, water with 5% soluble oil.

- Service Code 2: Plain water, diesel fuel

- Service Code 3: Most phosphate ester-based fire-resistant hydraulic fluids (e.g. Pydraul, Lindol, Cellulube, Fyrquel and Houghtosafe 1120) and petroleum-based solvents compatible with UHMWPE (Ultra-high Molecular Weight Polyethylene) dynamic seals and Viton static seals.

- Service Code 4: N/R

- Service Code 5: Skydrol and Aerosafe hydraulic fluid; acetone and some alcohols (ethyl, methyl, and isopropyl).

- Service Code 6: De-ionized water; de-mineralized water

Repair kit information:

- Fluid section seal kit P/N: 54614 (2 req’d)

- Air drive seal kit P/N: 57226

- Air valve seal kit P/N: 50881-2

- Optional tools: 28584 (Sleeve removal tool); 53565 (Bullet tool for pilot seal, 54312, extreme service air valve)

- Notes: Models manufactured before July 1999 and between January 2000 and September 2001 are equipped with the 50000 Cycling Valve and use Air Valve Seal Kit 51396-2. Models manufactured between July 1999 and December 1999 are equipped with the 50899-1 Cycling Valve and use Air Valve Seal Kit 50881, however, please contact factory to determine whether sleeves need to be updated. Models manufactured after September 2001 are equipped with the 50899-2 Cycling Valve and use Air Valve Seal Kit 50881-2.

- Installation documents: SKIS-001