Haskel has a strong reputation for quality, safety, and reliability, unrivaled expertise in high-pressure, liquid and gas transfer and pressurization technology, and the willingness to work closely with customers drives us to continually meet complex and critical challenges with innovative solutions.

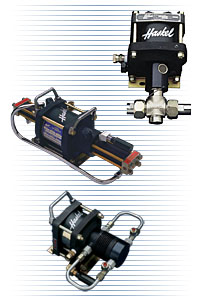

Haskel products are easy to install and control. Their compact size, minimal weight and ability to operate in any position makes them suitable for a wide range of mobile and fixed applications that involve generating, storing and controlling high-pressure gases and liquids.

Fluid Process Control Corporation is an Authorized Haskel Repair Center. We can repair and test any Haskel air-driven liquid pumps, gas boosters or air amplifiers in accordance with the factory specifications. This service includes replacement of all seals, as well as any other components that may be required following the initial evaluation. Our large inventory of Haskel repair kits and spare parts means a quick turn-around for most units. A written evaluation report is supplied along with a quotation for the actual repair cost of any unit sent in for repair. Please contact Fluid Process Control to get started.

Haskel Liquid Pump, Booster & Amplifier Sizing:

The information required to size a liquid pump, air amplifier, or gas booster includes:- Process media

- Air supply pressure available

- Available supply air capacity

- Desired outlet pressure

- Required flow rate

- Type of application (for example, continuous flow or filling a fixed size container)

- Gas supply pressure (for gas boosters)