Two Stage HYDROGEN Booster

See this product on the NEW Fluid Process Control website!

Description

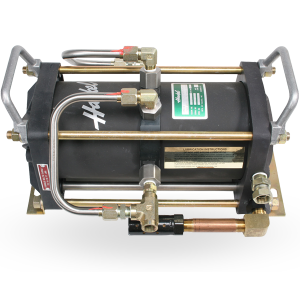

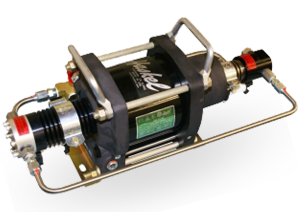

Haskel Model 86990 Air-Driven Hydrogen Gas Booster

Catalog literature: Gas Booster Catalog.pdf

NOTE: this is a version of the model AGT-7/30 Gas Booster modified for HYDROGEN service.

Features & Benefits:

- Reliable, easy to maintain, compact and robust

- No heat, flame or spark risk

- Infinitely variable cycling speed and output

- No electrical connections required

- Easy to apply automatic controls

- No limit or adverse affect to continuous stop/start applications

- Seal systems designed for long working life

- No air line lubricator required

- Suitable for most gases

- Ability to stall at any predetermined pressure and hold the fixed pressure without consuming power or generating heat

Technical Data:

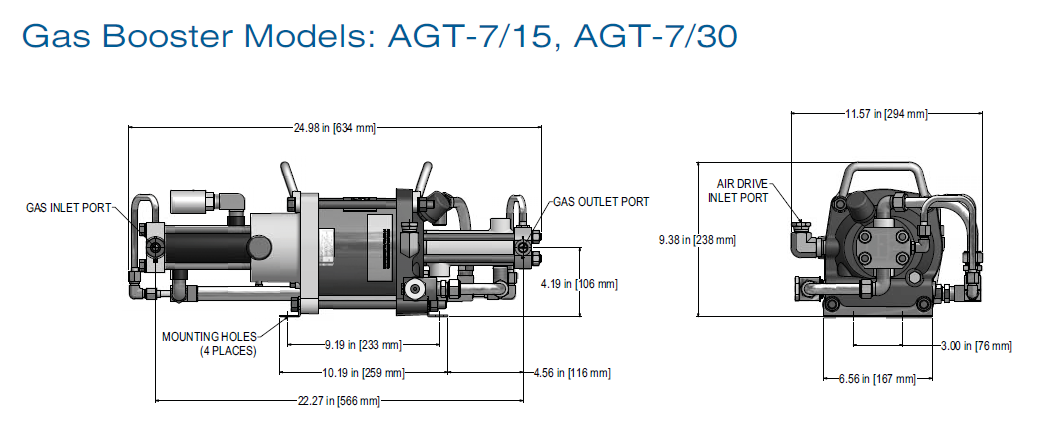

- BASE BOOSTER MODEL: AGT-7/30

- 1st Stage Ratio: -7

- 2nd Stage Ratio: -30

- Min HYDROGEN supply pressure: 25 psi

- Max HYDROGEN supply pressure: 2 Pa to 2500 psi

- Max rated HYDROGEN outlet pressure: 9000 psi

- Static outlet stall pressure formula: 30 Pa + 4 Ps (Pa = air drive pressure, Ps = GAS supply pressure)

- Min AIR drive pressure: 20 psi

- Max AIR drive pressure: 150 psi

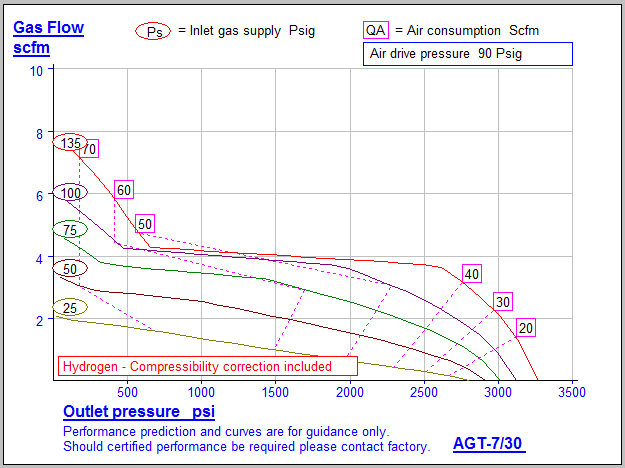

Sample Performance Characteristics:

- Boost 1.2 SCFM Gas from 50 psi to 2000 psi while using 40 SCFM Air @ 90 psig supply pressure

- Boost 1.9 SCFM Gas from 75 psi to 2000 psi while using 40 SCFM Air @ 90 psig supply pressure

- Boost 2.3 SCFM Gas from 100 psi to 2500 psi while using 40 SCFM Air @ 90 psig supply pressure

- Boost 2.6 SCFM Gas from 150 psi to 3000 psi while using 32 SCFM Air @ 90 psig supply pressure

Physical Characteristics:

- Unit weight: 41 LBS.

- Displacement / cycle: 13.2 cu. in.

- Max cycles: 60/min.

- GAS inlet/outlet connections: 3/8″ FNPT inlet & Interchangeable 3/8″ SAE or 1/4″ HP outlet

- AIR drive inlet port: 1/2″ FNPT