3-Way Ball Valve

Description

Catalog literature: 3-Way Ball Valves.pdf

Description:

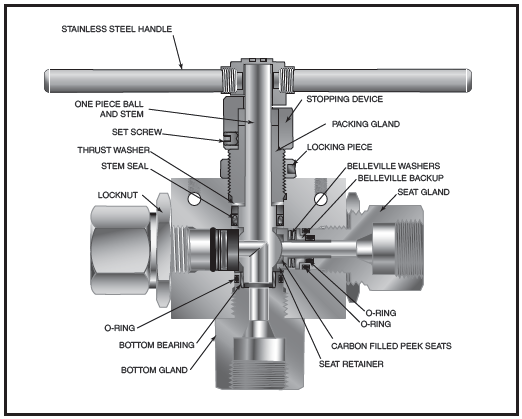

Parker Autoclave Engineers high-pressure ball valves have been designed to provide superior quality for maximum performance within a variety of valve styles, sizes, and process connections. Some of the more unique design innovations include an integral one-piece trunnion mounted style ball and stem that eliminates the shear failure common in two piece designs, re-torqueable seat glands that result in longer seat life, and a low friction stem seal that reduces actuation torque and enhances cycle life.

These ball valves can also be modified to incorporate the use of special materials, seals for high temperature applications, subsea models, and valve actuators.

When it comes to high-pressure applications, these ball valves with the associated high-pressure components, provide the critical performance demanded by the high pressure market.

Features:

- One-piece, trunnion-mounted style, stem design eliminates shear failure and reduces the effects of side-loading found in two-piece designs

- Re-torqueable seat glands for longer seat life

- Carbon-filled PEEK seats offer excellent resistance to chemicals, heat, and wear/abrasion

- Full-port flow path minimizes pressure drop

- 316 cold-worked stainless steel construction

- Low friction pressure-assisted graphite-filled PTFE stem seal increases cycle life and reduces operating torque

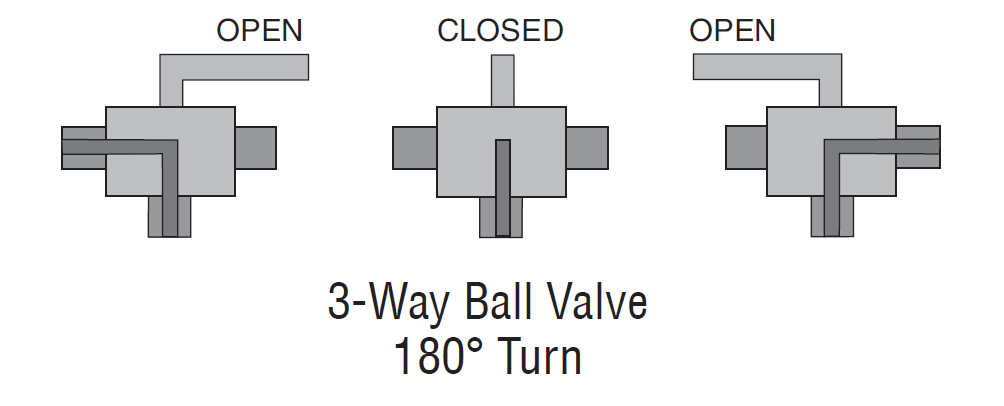

- Available in 90-degree turn diverter and 180-degree turn switching models

- Viton o-rings

- Wide selection of tube and pipe end fittings

Options:

- Optional o-ring materials for high-temperature applications

- Optional wetted materials

- Electric or pneumatic actuators

Technical Data:

- Operating pressure: 10,000 PSIG

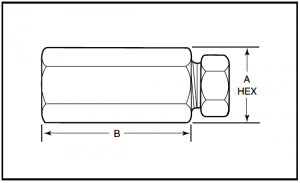

- Connection size: 3/4″

- Connection type: S750CX20 (Medium Pressure Coned-and-Threaded)

- Ball orifice diameter: 0.500″

- Minimum orifice diameter: 0.500″

- Temp range: 0 to +400F

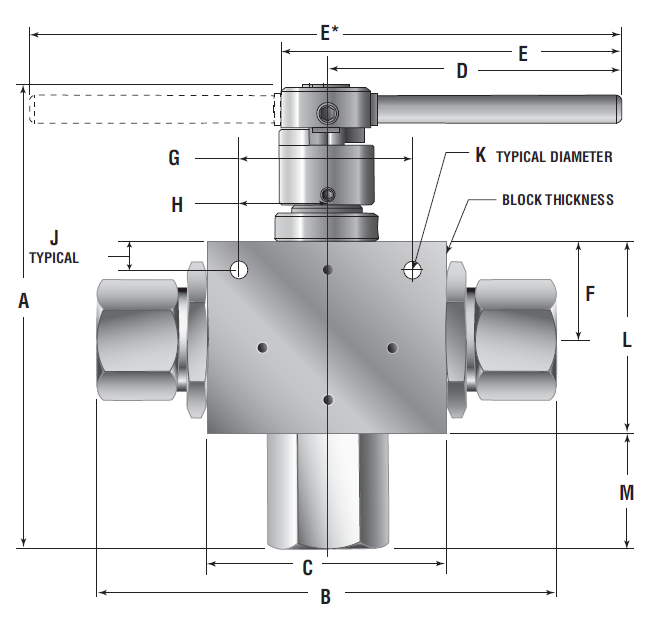

Dimensions:

- “A”: 7.83″

- “B”: 7.77″

- “C”: 4.13″

- “D”: 5.12″

- “E”: 10.25″

- “F”: 1.66″

- “G”: 3.00″

- “H”: 1.50″

- “J”: 0.50″

- “K”: 0.28″

- “L”: 3.34″

- “M”: 1.70″

- Block thickness: 1.75″