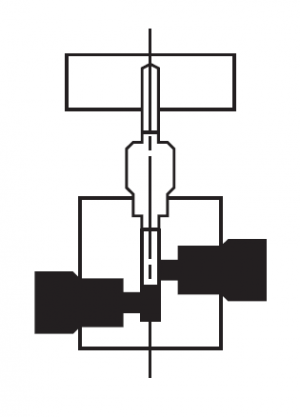

10,000 PSIG Needle Valve

Description

Parker Autoclave Engineers Model SW8882 10,000 PSIG Needle Valve

Catalog literature: Low Pressure Needle Valves.pdf

Principle of Operation:

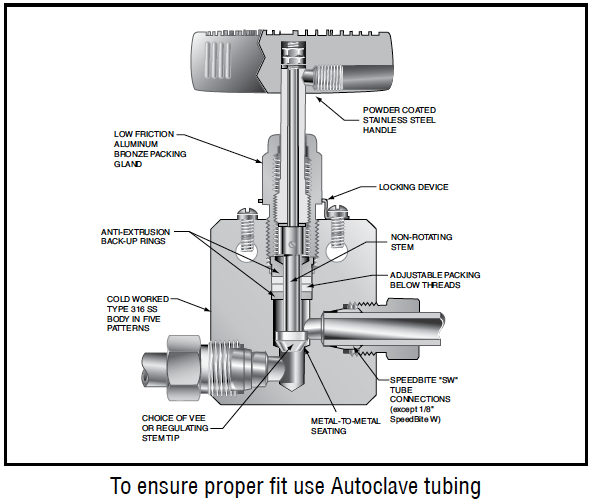

The Low Pressure (15,000 psig maximum), otherwise known as “SpeedBite”, Needle Valves are designed for applications between traditional compression fittings and the Parker Autoclave Engineers’ Medium Pressure coned-and-threaded products that are designed for high flow and high pressure. SpeedBite valves are engineered for use with annealed ASTM A269 316 (and similar) Stainless Steel tubing designed by Parker Autoclave Engineers to a controlled hardness. SpeedBite valves employ a bite-type compression style single ferrule that is manually “set”. 1-1/4 rotation from tube grip forces the ferrule into a tapered seat and causes the leading edge of the ferrule to bite into the tubing, creating a shoulder for positive mechanical support of the tubing. When correctly installed, connection strength far exceeds the burst pressure of the tubing utilized.

Low Pressure Valve Features:

- Temperature rated for -100F (-73C) to +650F (+343C), depending on packing materials

- Designed for use with Low Pressure “SpeedBite” single ferrule compression fittings and tubing

- 10V-series valve design provides for 1/8″ tube size connections

- SW-series valves are constructed for tube sizes from 1/4″ to 1/2″ OD

- UNS S31600/S31603 cold-worked 316/316L SS body construction is standard; optional materials available upon request

- Non-rotating stem prevents stem/seat galling

- Metal-to-metal seating achieves bubble-tight shutoff , longer stem/seat life, greater durability for repeated on/off cycles and excellent corrosion resistance

- Valves can be used in liquid or gas applications

- PTFE packing below stem threads provides dependable stem and body sealing; optional packing materials available upon request

- Choice of Vee (shutoff) or Regulating (flow control) stem tips

- Optional N-Dura stem and/or replaceable seat coating or Stellite material option for severe service applications

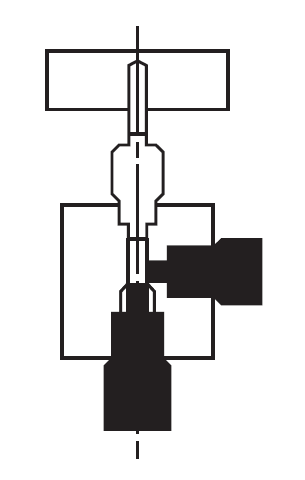

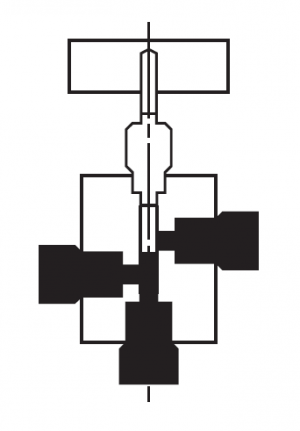

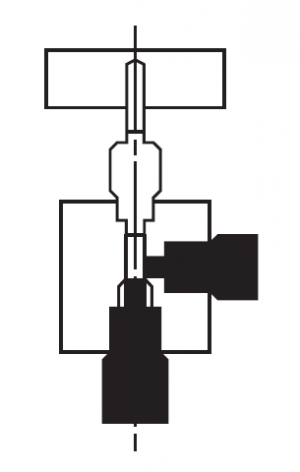

- Available in five body patterns

Technical Data for valve P/N SW8882:

- Operating pressure: 10,000 PSIG @ RT

- Configuration: 2-way Angle/Replaceable seat

- Connection size: 1/2″

- Connection type: SW500 (SpeedBite compression)

- Stem type: Regulating

- Packing: PTFE

- Temp range: -100 to +450F

- Orifice diameter: 0.375″

- Cv: 1.9

Valve Packing Options:

Standard Parker Autoclave Engineers valves with PTFE packing may be operated between temperatures of 0F (-18C) and +450F (+232C). Extreme temperature packing for applications from -100F (-73C) to +650F (+343C) available by adding the following suffixes to the catalog order number:

- “SW8882-B” : Cryogenic trim materials and PTFE packing; required for temperatures between -100F (-73C) and 0F (-18C)

- “SW8882-TG” : standard valve with Teflon-glass packing; for temperatures between -100F (-73C) and +600F (+316C)

- “SW8882-GY” : standard valve with graphite-yarn packing; for temperatures up to +650F (+343C)

NOTE: Parker Autoclave Engineers does not recommend compression sleeve connections below -100F (-73C) or above +650F (+343C). For higher or lower temperatures, coned-and-threaded connections must be used.

Standard Repair Kit part number: RSW8882

Valve Options:

- Pneumatic valve actuators

- Electric valve actuators

- High or low temperature extended stuffing box (NOTE: not typically used with Low Pressure Valves because of the temperature limitations of the SpeedBite connections)

- Stem extender

- Clam-shell handle lockout