14″ Two-Stage Gas Booster

Description

Haskel Model 14AGT-125/315 Air-Driven Gas Booster

Catalog literature: Gas Booster Catalog.pdf

With a nominal 1st stage pressure ratio of 125:1 and a nominal 2nd stage pressure ratio of 315:1, the Haskel model 14AGT-125/315 14″ Two-Stage Gas Booster utilizes air pressure to boost gas pressures to a maximum of 35,000 psi PSIG.

Features & Benefits:

- Reliable, easy to maintain, compact and robust

- No heat, flame or spark risk

- Infinitely variable cycling speed and output

- Pneumatic driven units do not require electrical connections

- Easy to apply automatic controls

- No limit or adverse affect to continuous stop/start applications

- Seal systems designed for long working life

- No air line lubricator required

- Hydrocarbon free – separation between air and gas sections

- Built-in cooling (most models)

- Suitable for most gases

- Ability to stall at any predetermined pressure and hold the fixed pressure without consuming power or generating heat

Technical Data:

- 1st Stage Ratio: 125:1

- 2nd Stage Ratio: 315:1

- Min GAS supply pressure: 1000 psi

- Max GAS supply pressure: 82 Pa to 6000 psi

- Max rated GAS outlet pressure: 35,000 psi

- Static outlet stall pressure formula: 315 Pa + 2.5 Ps (Pa = air drive pressure, Ps = GAS supply pressure)

- Min AIR drive pressure: 20 psi

- Max AIR drive pressure: 130 psi

- Interstage Relief Valve Set Pressure: 15,000 psi

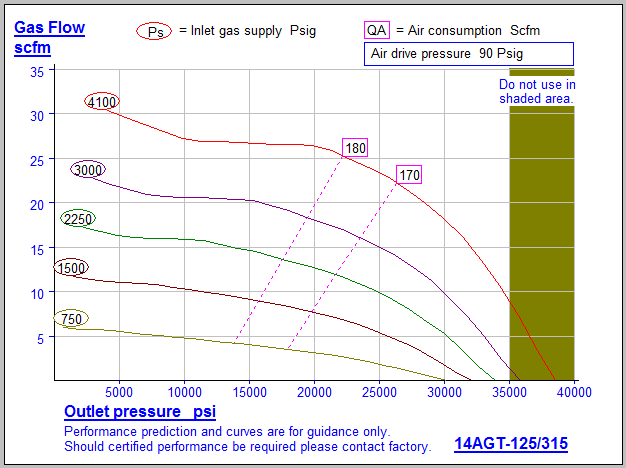

Sample Performance Characteristics:

- Boost 4.2 SCFM Gas from 1,000 psi to 18,000 psi while using 150 SCFM Air @ 90 psig supply pressure

- Boost 10 SCFM Gas from 2,200 psi to 24,000 psi while using 150 SCFM Air @ 90 psig supply pressure

- Boost 13 SCFM Gas from 3,100 psi to 28,000 psi while using 133 SCFM Air @ 90 psig supply pressure

- Boost 14.9 SCFM Gas from 4,100 psi to 32,000 psi while using 115 SCFM Air @ 90 psig supply pressure

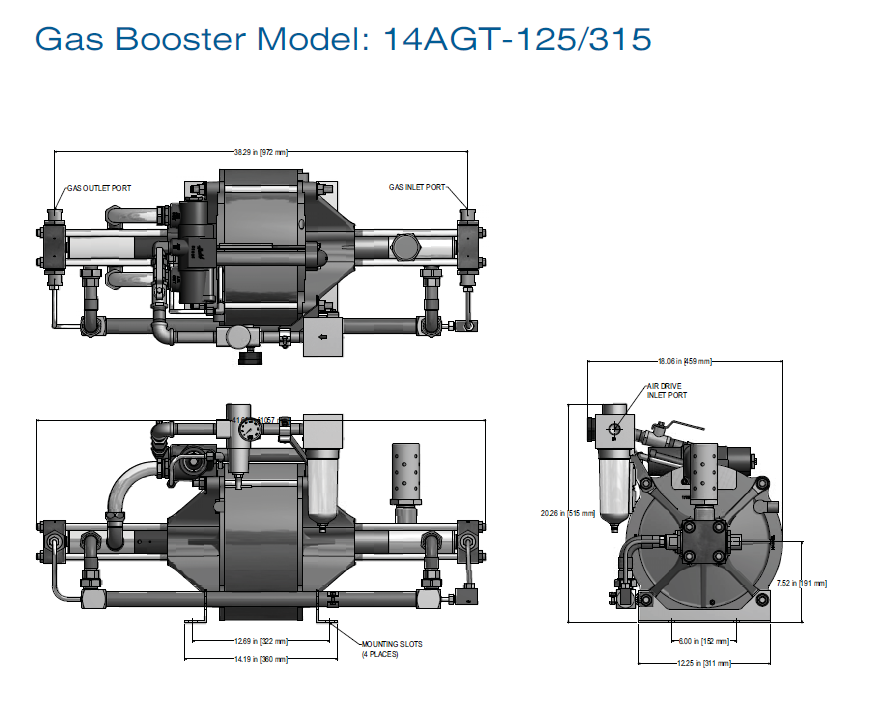

Physical Characteristics:

- Unit weight: 154LBS.

- Displacement / cycle: 4.44 cu. in.

- Max cycles: 40/min.

- GAS inlet/outlet connections: 3/8″ HP

- AIR drive inlet port: 3/4″ FNPT

Repair kit information:

- Gas section seal kit P/N: 28348 & 28349

- Air drive section seal kit P/N: 28426

- Air valve seal kit P/N: 50881

- Optional tools: 28584 (Sleeve removal tool)

- Notes: P/N 28348 & P/N 28349 kits include piston and check valves seals. Units manufactured prior to Jul. 1999 and between Jan. 2000 and Sep. 2001 are equipped with the 50000 cycling valve and use Air Valve seal kit #51396-2. Units manufactured between Jul. 1999 and Dec. 1999 are equipped with the 50899-1 cycling valve and use Air Valve seal kit #50881 (please contact FPCC to determine whether sleeves need to be updated). Units manufactured after Sep. 2001 are equipped with the 50899-2 cycling valve and use Air Valve seal kit #50881.

- Installation documents: SKIS-001 SKIS-002