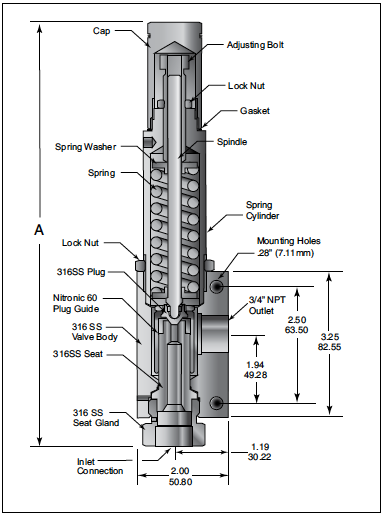

Metal-Seat Relief Valve

Description

Catalog literature: Autoclave Relief Valves.pdf

Description:

Series RVP relief valves provide reliable venting of gases or liquids at set pressures between 3,000 psig and 75,000 psig. These precision valves are designed for pressure gas systems, cryogenic systems, petrochemical applications and other special systems. Capable of handling air, gases, steam, vapor and liquids, they are not recommended for steam boiler applications, nor are they ASME code stampable.

Features:

- Materials: standard relief valves are constructed in 316SS with select components made of anti-galling stainless steel material for optimum economy and ruggedness.

- Full lift for full flow: these relief valves are designed to open as a function of increasing system pressure. Proper spring selection assures repeatability of opening, full lift and flow, and reseat pressures.

- Reliability and long service life: materials engineering and stringent quality control procedures combine to assure the highest quality, reliability and service life. Each valve is pre-set and factory sealed to ensure proper valve operation.

- Dependable shutoff: series RVP relief valves are designed to provide shut-off of liquids and gases under pressure to commercial tightness standards. Series RVS relief valves are designed to provide bubble-tight shut-off of gases.

- Fewer parts / ease of maintenance: Engineered to perform with fewer basic components, both RVP and RVS valves facilitate minimum stocking of spare parts and ease of maintenance. The combined angle seat in the RVP series eliminates the need for lapping in rework.

- Special requirements: Most models available with CE mark. SOG options available upon request.

Technical Data:

- Min set pressure: 30,000 PSIG

- Max set pressure: 60,000 PSIG

- Inlet connection: 3/8″ High Pressure (F375C)

- Outlet connection: 3/4″ FNPT

- Temp range: -423 to +400F

- Orifice diameter: 0.078″

- “A” dimension: 9.52″