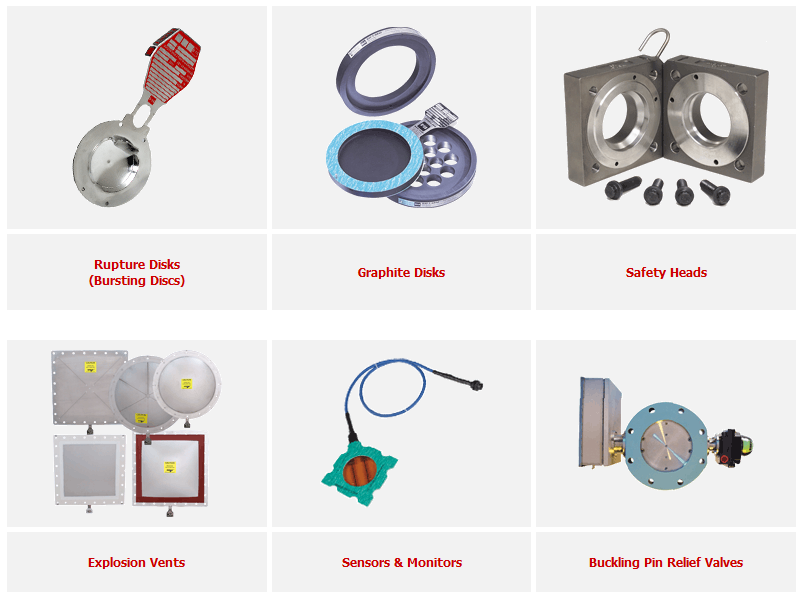

BS&B Safety Systems products include:

REVERSE BUCKLING DISKS

The Reverse Buckling disk represents the best in rupture disk (bursting disc) technology. Invented by BS&B, our range of reverse buckling products provides a pressure relief solution for burst pressures ranging from a few inches of water column / a few millibar to over 70,000 psig / 4800 bar.

Burst pressure is accurately controlled by a combination of material properties and the shape of the disk domed structure. By loading the Reverse Buckling disk in compression it is able to resist operating pressures up to 100% of minimum burst pressure even under pressure cycling or pulsating conditions.

Designed for non fragmentation upon activation, Reverse Buckling disks are recommended for combination with pressure relief valves to isolate them from normal process conditions ensuring excellent leak tightness, reduced valve maintenance expenses and often allowing the use lower cost valve trim.

FORWARD ACTING DISKS

Forward acting, or conventional rupture disks (bursting discs) have been a mainstay in process applications since BS&B developed the first rupture in 1931. Developed in 1934, the Type B disk, the "granddaddy" of all rupture disks (bursting discs) is still the disk-of-choice in many applications.

Applying load to the concave side, the disk is subjected to tension forces. Forward acting disks regulate burst pressures by the tensile strength of the material.

For low burst pressures, the Type D disk has a slotted metal top section and a metal or fluorocarbon seal. For higher operating ratios, the scored NU-SAF family of disks is often selected for polymerization processes. Our VAC-SAF line offers protection from excessive vacuum or overpressure.

For tank car applications, the ITC disk protects intermodel tank containers while the SR-TC is a surge resistant disk for railroad took cars and over-the-road trailer service industry.

A wide range of standard rupture disk (bursting disc) assemblies is available for your specific application. These Threaded and Welded Assemblies are discarded after disk rupture. Customized designs are available for customer applications that cannot be met using standard assembly designs.

BS&B manufactures each graphite rupture disk (bursting disc) from a pure block of graphite. By impregnating the porous graphite with resin, you can be assured of a product that can withstand almost any aggressive chemical attack. Our manufacturing process achieves:

Wide range of sizes from 1/2" (12mm) to 60" (1200mm)

Superior corrosion resistance

Operating temperatures up to 400º F, rising to 800º F with the Hi-Temp Assembly (HTA) upstream of a disk Large burst pressure range (0.25 - 1000psig) (0.017 - 70 Bar)

Zero manufacturing design range

Tight burst pressure tolerances

Supplied complete with gaskets for immediate installation and reduced downtime

Elevated temperature testing at no additional charge

Low KR (Flow Resistance) – Consult BS&B

Many designs and types of fittings are used as holders for rupture disks (bursting discs) and are fabricated from metal(s) compatible with the process media and atmospheric environment. Each BS&B safety head is designed for optimum safety and performance.

Reduced Inventory Costs. One head fits most standard international flanges eliminating the need to stock unnecessary and costly inventory.

Simple, Fail-Safe Installation. The asymmetric locating pins and standard welded J-Bolt ensure correct orientation by eliminating possible human error.

Leak-Tight Bite-Type Seal. BS&B is the only disk manufacturer who machines a Bite-Type seal into the inlet flange of the Safety Head that engages the disk material proper creating a bubble-tight seal.

Easy Cleaning and Inspection. Maintenance can be done without replacing the disk due to the pretorqued cap screws, which maintain the clamping load on the disk.

For conventional pre-bulged rupture disks (bursting discs) we offer Bolted Type Safety Heads. Where space is limited and where quick or frequent change-out of rupture disk may be necessary, the Union Type Safety Head is available.

With a unique curved design, the LO-TO-FLO™ Safety Head limits process buildup to ensure superior over-pressure protection for high viscosity liquids.

Whether your process requires a Sanitary / Aseptic Fitting or a QUICKSERT™ flat-faced flange assembly holder, BS&B offers the right safety head for your application.

Whether your application involves dust, gas or mist, BS&B explosion vents provide reliable relief at or below their rated burst pressure, even if damaged. They require little maintenance and are easy to replace.

BS&B explosion vents like the Vent-Saf® Plus produce a controlled full opening and are non-fragmenting. Vent-Saf® Plus explosion vents have been certified under cycle testing to over one million pressure/vacuum cycles and meet all NFPA 68 and ATEX Standards.

Alert Sensors® provide immediate warning of a ruptured disk when used with a BS&B Burst Disk Monitor or other suitable electrical monitoring equipment. When a disk or vent ruptures, the process flow through the device causes the sensor's conductive circuit to break. The disruption of the current flowing through the circuit activates a Burst Disk Monitor (BDM) or other suitable electrical monitoring equipment to give a visual and/or audible signal.

Features of BS&B Monitors and Sensors

Instant Notification of a Ruptured Disk

Quicker Corrective Action

Activates Valves/Pumps to Control or Shut-Down Process

Lessens Critical Downtime

Reduces Product Loss

Minimizes Environmental Pollution

Buckling Pin technology offers an accurate and reliable means of calibrating pressure relief devices. BS&B has developed the BPRV™ Buckling Pin Relief Valve for in-line pressure or vacuum relief offering quick and simple external resetting. The BPRV is suitable for both gas and liquid applications, and provides a full relief opening at a pre-determined set pressure.